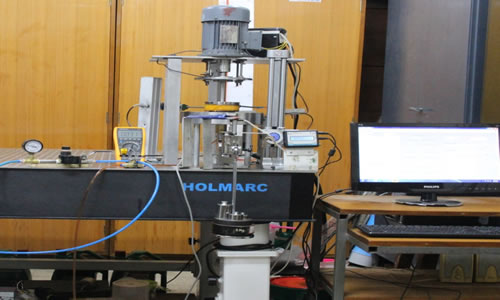

Experimental Facility

The instrument is suitable for conducting friction and wear study under dry/lubricated contact regime. Both rotating and linear reciprocating modules are available with following test configurations: pin-on-disc; ball-on-disc; pin-on-plate; ball-on-plate; and chip-on-plate. High vacuum control kit is also available for the tribometer chamber. Penetration depth, coefficient of friction, and friction force are measured in time domain, and the results can be visualized and interpreted through computer interface. The instrument was supplied by CSM Instrument. more information for user

This standard instrument is widely used for estimating lubricants performance under nearly boundary lubrication condition. The instrument is mainly used for characterizing anti-wear (AW) and extreme-pressure (EP) additives performances according to various standards. Generally, EP performance is indicated by the seizure load, and AW performance is indicated by the dimension of wear scar on ball surface. more information for user

This particular instrument provides visual interpretation of film thickness between a rolling sphere and a disc under EHL regime. An adjustable microscope (50x) is used to observe the optical fringes created through optical interference during relative motion. Effects of loads, speeds, materials, and lubricants on film thickness can be experimentally studied with the present instrument.

This module is useful for understanding two important tribological phenomena such as stick-slip and friction induced vibration. The transition from static to kinetic friction and their differences can be well demonstrated; moreover, effects of load, speed, material, and lubricants/lubrication on stick-slip are meaningfully indicated by this experimental module. The indications are mostly restricted to demonstration purpose.

This rheometer is useful for determining the strain rate response and viscosity for wide range of fluids. This particular instrument has a standard rotating cylinder with cone tip type arrangement. The instrument can be well employed for characterizing Newtonian and non-Newtonian rheology of various lubricating oils and greases. A temperature control circuit is also added to the system for studying viscosity-temperature characteristics of lubricants. more information for user

This is a portable mechanical stylus type surface roughness measuring instrument. Various statistical parameters of the following profiles: P; R; DIN4776; MOTIF.R; and MOTIF.W can be measured. The instrument is available with scan sizes of 0.4 mm, 1.25 mm, 4 mm, 8 mm, and 12.5 mm and with vertical resolution of 0.01 μm.

Atomic Force Microscope:

An important tool for characterizing physical nature of surfaces and a useful instrument in current tribology research trends. The present instrument is suitable for wide scanning in contact mode with maximum horizontal resolution of 110 ×110 (μm) and vertical resolution of 22 μm. Both constant force and constant height modes are available. The instrument is also integrated with video microscope with necessary software package to obtain real time video imaging of AFM probing.

3D Surface Profilometer:

This is a non-contact optical profilometer for three dimensional imaging of surface topography. The instrument works on the principle of confocal microscopy and thus has large range of spatial scanning resolution. Both 2D and 3D surface profiles and corresponding statistical roughness parameters can be obtained for various materials and surfaces.

Instrumented Micro indentation and Scratch Tester:

This indenter is being used for evaluating various mechanical properties of surfaces such as elastic modulus, hardness, elastic energy, plastic energy, creep etc. The instrument is also capable of determining the mechanical properties of surfaces as function of depth. Instrumented indentation can be done for load range from 10 mN to 10N. Indentation testing with maximum load up to 30N can be done with optical measurement. This is also integrated with a scratch testing facility, and can be used for determining adhesion and wear characteristics of different materials. The instrument follows various ISO, ASTM, DIN, and JIS standards recommended for indentation and scratch testing of different metals, polymers, and ceramics. more information for user

This test rig has been built in house and put in use for conducting experimental research on lubrication and sealing performances of micro textured bearing pads.

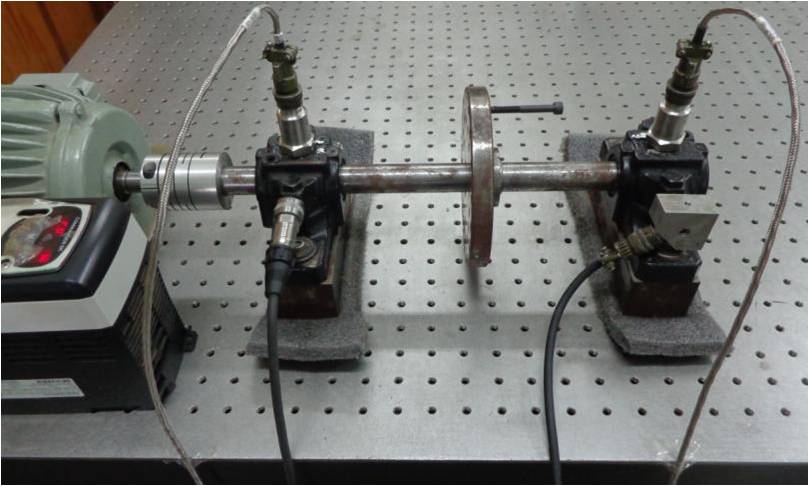

This is a scaled down model which closely resemblance the rotor system in steam turbine plant. The model has been built in house for experimental estimation of bearing characteristics such as stiffness and damping.

This instrument is useful for conducting experiments on three body abrasive wear for different material pairs. The instrument has block-on-rim set up with an arrangement for external supply of abrasive particles at the interface.

The test rig is suitable for obtaining hydrodynamic pressure profile in a journal bearing system.

This machine fault simulator has been put in use for investigation on various bearing faults.

This robust test rig is useful for conducting experiments on friction and wear characteristics of different material pairs under high load and speed conditions. With pin-on-disc and/or ball-on-disc arrangements, both dry and lubricated contact studies are performed with the instrument.

These hip, knee, and shoulder joint simulators were designed and built in-house. These typical instruments facilitate to characterize tribological performances for bio-compatible materials for artificial orthopaedic implantation. By taking load and displacement time histories into account these devices simulate the forces, which exerts at different bone joints during normal walking and running of human being. These simulators are equipped with cam runner and stepper motor to keep control over the motions and to efficiently measure the corresponding forces and moments at the joints. Moreover, the joints have replication of bone models, so the devices closely simulate the real geometrical situation. Several sophistications may be possible; however, these particular simulators are cost effective, easy to manufacture, and can be used for testing wide variety of bio-compatible materials.

r