In House Developement

Hybrid Thrust Pad Bearing Set-up (Hydrostatic or Hydrodynamic Lubrication and/or both)

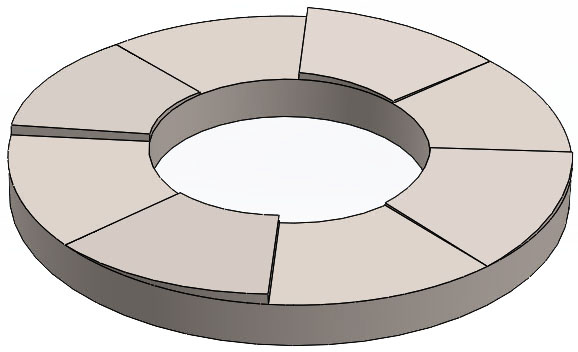

The objective of the present invention is to provide a high-performance hybrid thrust pad bearing set-up with constant flow system which can operate under hydrostatic or hydrodynamic lubrication and/or combination of both, and capable of maintaining excellent bearing performance throughout a long period. The main aim of this invention is to test thrust pads having different modified surfaces (textured, groove/sector, inclined, and/or tilting pad surface) to measure frictional torque, recess pressure, temperature of outlet oil and oil film thickness (i.e., bearing clearance) under varying speed, load and supply pressure conditions.

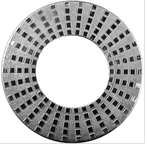

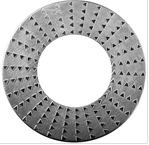

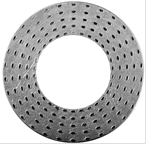

The above examples figure shows the different Thrust Pad namely (a) Plane Pad, (b) Inclined Pad, (c) Sector Pad and (d) Textured Pad Specimens used for Testing.

This novel construction includes a method of designing a thrust bearing system having changeable bearing pads, where thrust pad bearings having different geometric dimensions (i.e., variable thickness with different inner and outer diameter of pad) can be accommodated. The diameter of recess is maintained at 50 mm for the present set-up, therefore various outer diameter size of thrust pad specimens can be tested when the inner diameter is 50 mm or lower. Furthermore, inner dimeter of more than 50 mm can also be accommodated by changing the recess diameter to the size in the recess block.

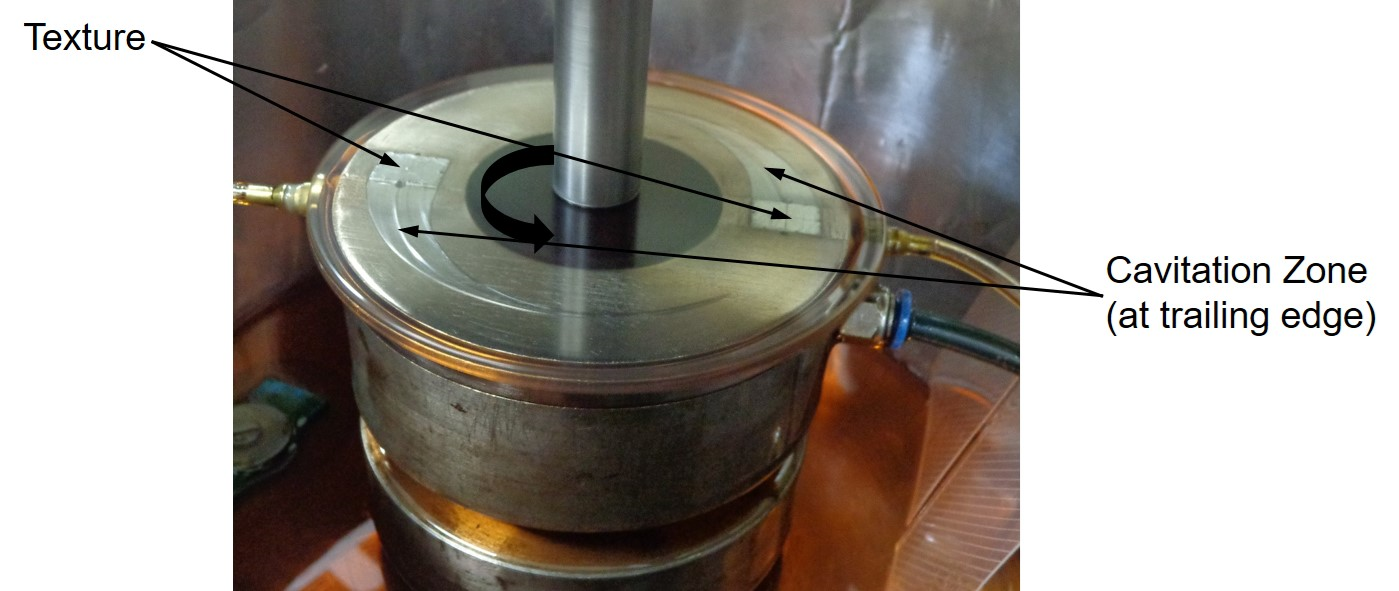

Developed Working Setup in Laboratory.

Use of a transparent runner can help to visualize and understand the online condition such as cavitation effect on land portion of the thrust pad specimen.

Cavitation Zone Profile on Texture Pad

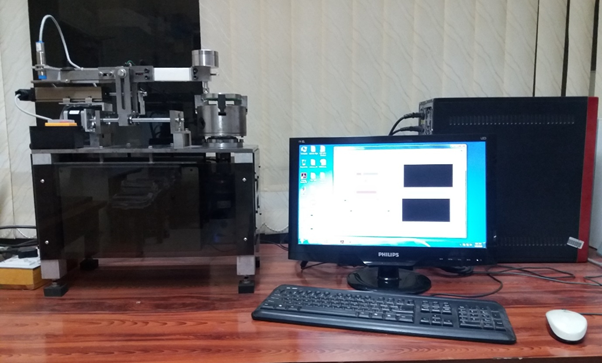

Spiral Tribometer

This invention is aimed at providing the cost effective solution for reliable test set-up. The pin/ball-on-disk tester is one of the best known and most widely used tribotesters. This is used for determining the tribological characteristics of different materials under various load and speed. A stationary pin/ball mounted on a holder is brought into contact against a rotating disc at a specified speed as the pin/ball is sliding. Pin/ball position, normal load and speed can be set as desired (or automated by the software optionally) .The output result is the friction force which is acting between the pin/ball and disc and wear in terms of penetration depth of pin/ball. This tribometer can run in spiral tracks, apart from the rotation of disk the pin/ball can move linearly to simulate this spiral track. This always expose new surface for contact/rubbing, thereby will be helpful to study the interaction of new machine elements. The system is completely control through computer to achieve robustness and accuracy.

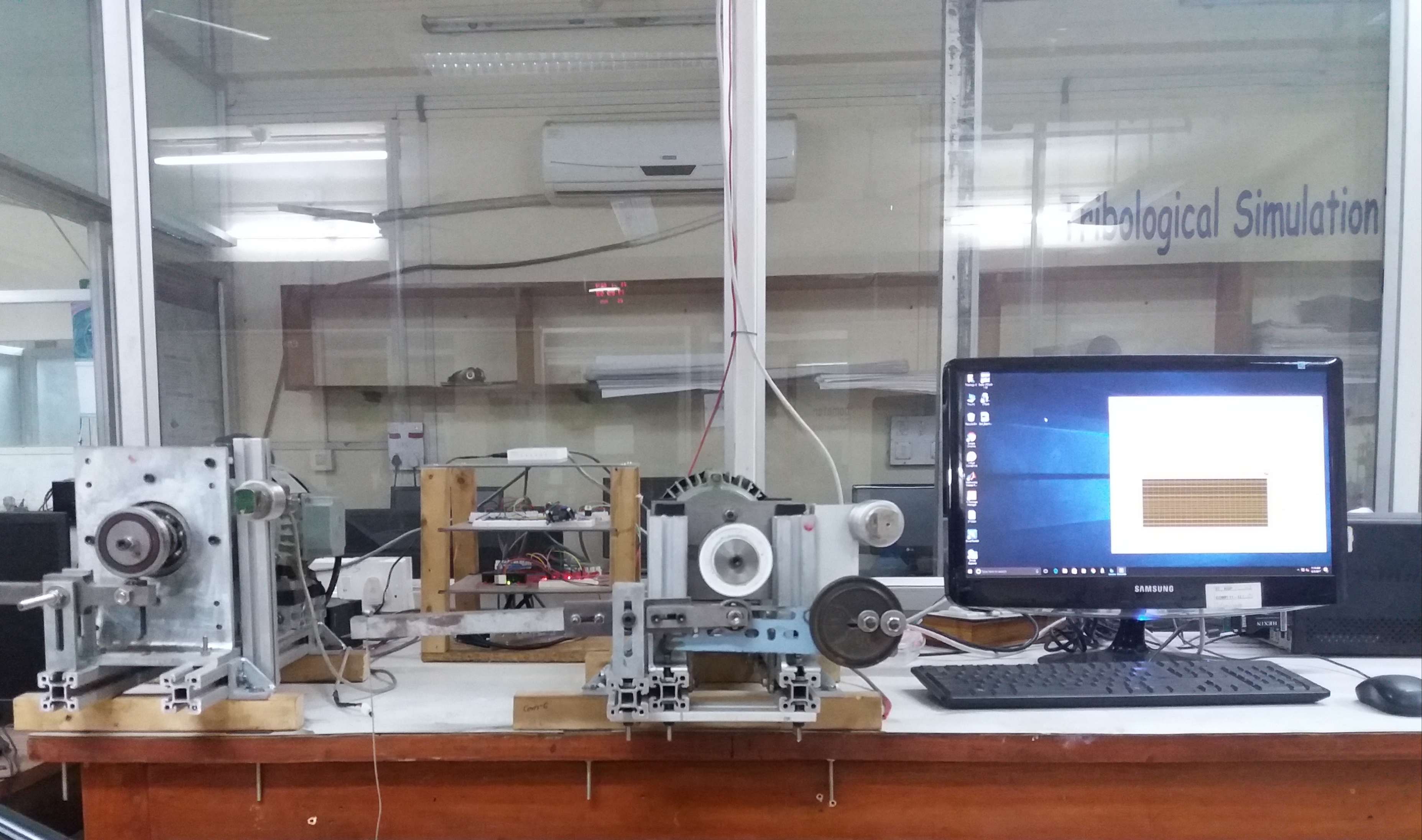

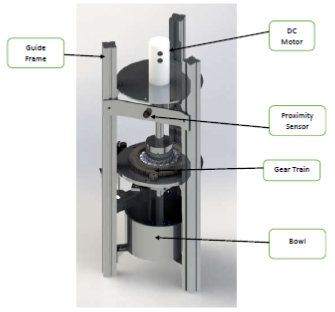

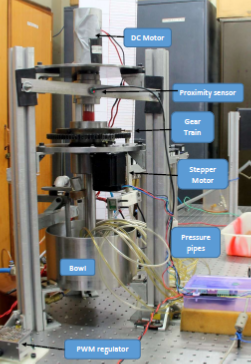

Rolling Element Bearing Test Rigs

The aim is to develop and utilise affordable low cost rolling element bearing test rig to perform condition check and life improvement study of bearings. The modular bearing mounting design helps to accommodate wide range of bearing dimensions for testing. The bearings can be loaded using dead weight and speed of the bearing can be varied with the help of VFD controlled 3-phase motors. The condition of bearing is monitored throughout the test by means of measuring the friction, temperature and motor current signature. Further, grease purge can be detected through motion sensitive video monitoring. The test rigs are intended to run for days to simulate the life of the bearings with automated safety features implemented in software. Complete operation and control of test rig is achieved through associated computer and software. Multiple test rigs can be integrated easily to one computer and software having freedom to run the rigs individually/together with different input parameters.

Journal Bearing Test Rig

The attempt was to make journal bearing test rig affordable. Present design of journal bearing test rig helps to understand the pressure development and profile inside bearing in various loading and speed conditions. Viscous friction and full 360 pressure profile can be monitored through associated software from a computer.

Deterministic Micro-Texturing on Metal Surfaces

The present invention relates to a process for producing positive deterministic micro textures on mild steel surface using photo chemical machining. Fabrication of surface micro-texture by current technique is conceived in two-stages: where photographic emulsion process is used to pattern the microstructure, and chemical etching method is employed to fabricate the textures on mild steel surface by dissolving exposed metal surface material. According to invention, the chemical solution required for etching is prepared by mixing suitable chemicals with hot water (around 60-70° C), under controlled conditions of concentration and temperature to achieve the desired result. The mild steel specimen having texture images printed on its surface by photographic emulsion process is immersed in the etching solution such that the metal portion directly exposed to solution will be chemically etched to form the texture of desired geometry (i.e., shape and size), where depth of the texture (i.e., texture height) is controlled by varying the etching time. The basic advantage is that the texture fabricated by present invention is having smooth etched bottom surface with sharp edge and the process is also cost effective. This method produces burr free and intricate design metal components of any desired geometry (i.e., shape and size) with close tolerances. The fabrication of surface texture in this method inherits all the properties of parent metal.

Various surface textures fabricated using present process are shown below:

Textured Surfaces of Different Shape i.e. Square, Circle, Triangle and Elliptical Fabricated in Laboratory

Any type of engineering texture shapes those are printable in computer can be fabricated by using current technique owing to patterning of complex structure through photographic emulsion process. Fabrication of textures with square, circular, triangular and elliptical shape are shown above. All the texture shapes as shown are having base dimension of 2300 µm and texture height of 160 µm (approx.).